Product Categories

Accurate and informative data are the key to research discovery and routine testing. At SiMPore we strive to develop sample preparation substrates and membrane filtration products that enable superior data capture and analysis. Our substrates are tailored to provide unmatched performance for a variety of applications.

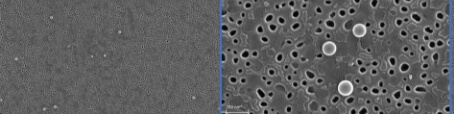

Ideal substrates for X-Ray microscopy and spectroscopy, compatible with a range of vacuum and temperature conditions.

Advanced Technology

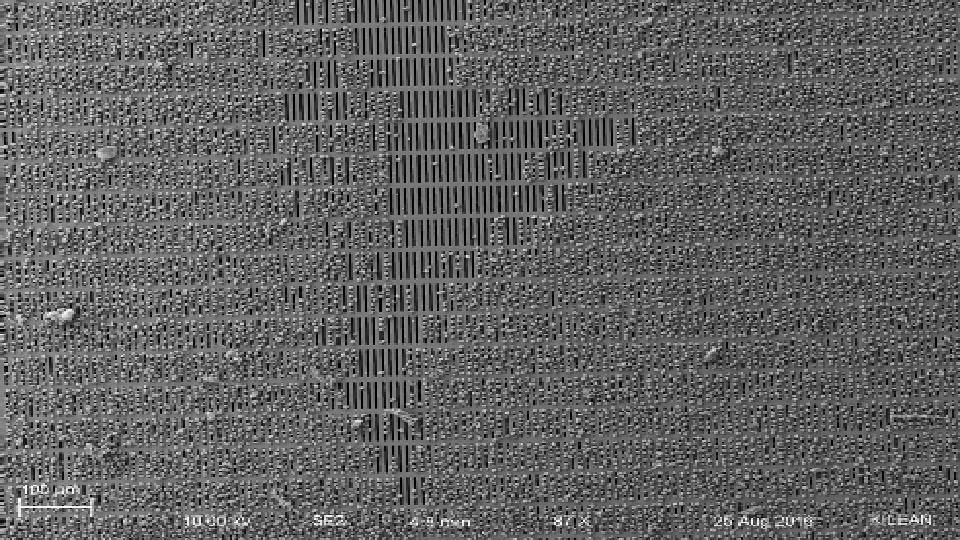

We use proprietary etching methods and the latest in MEMS and thin-film processing to fabricate freely suspended silicon membranes.

Custom Fabrication

No matter your membrane application, we’ll ensure the perfect product to meet your unique needs.